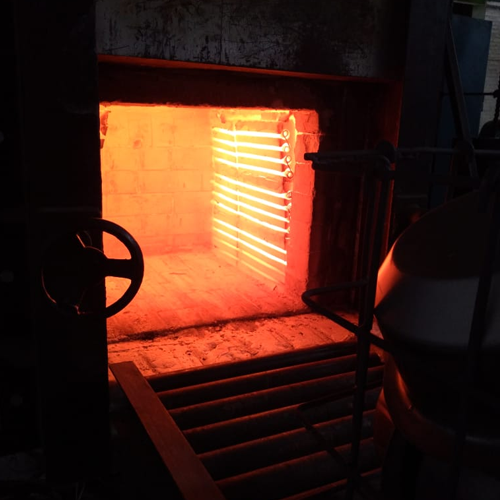

Muffle Furnace

Vishvakarma Electronics (Regd.) manufactures custom designed, muffle and sintering furnaces for heat treating and sintering applications. Our world-class muffle furnace designs are specifically sized and designed to meet the specific requirements of your application. Whether you are looking for a muffle furnace design for a new process or a replacement furnace or parts for an existing production line, Vishvakarma Electronics (Regd.) staff will help you select the best muffle materials and sintering furnace design for your application.

Our Industrial Muffle & Sintering Furnace are used for high temperature applications such as: annealing, tempering, hardening, and sintering applications. Vishvakarma Electronics (Regd.) standard line of furnaces offers a wide range of options and we offer a line of custom furnaces to meet unique requirements.

Features of our muffle and sintering furnaces include

» Alloy muffles designed for temperatures up to 2,000°F

» Indirect heat supplied by electric glow bars surrounding the outside of the muffle

» Controlled heat up and cool down rates

» Stainless steel or ceramic slide beds

» Mesh belts

» Inert gas atmospheres and supporting equipment

» Flame curtains and seals at entrance and exit

» Chamber length requirements are met by flange connecting standard length sections

» Microprocessor-based temperature controls

» Data acquisition systems for logging critical process information

» Heavy gauge steel shell construction with lightweight, energy-saving insulation

We make it our job to understand your industry and have experience in providing solutions for your manufacturing challenges. Our engineers meet with each customer to determine your exact requirements and select the best industrial sintering furnace configuration for your application. Vishvakarma Electronics (Regd.) offers expert installation services and maintenance services, so you can be assured your furnace will perform at maximum efficiency and effectiveness.